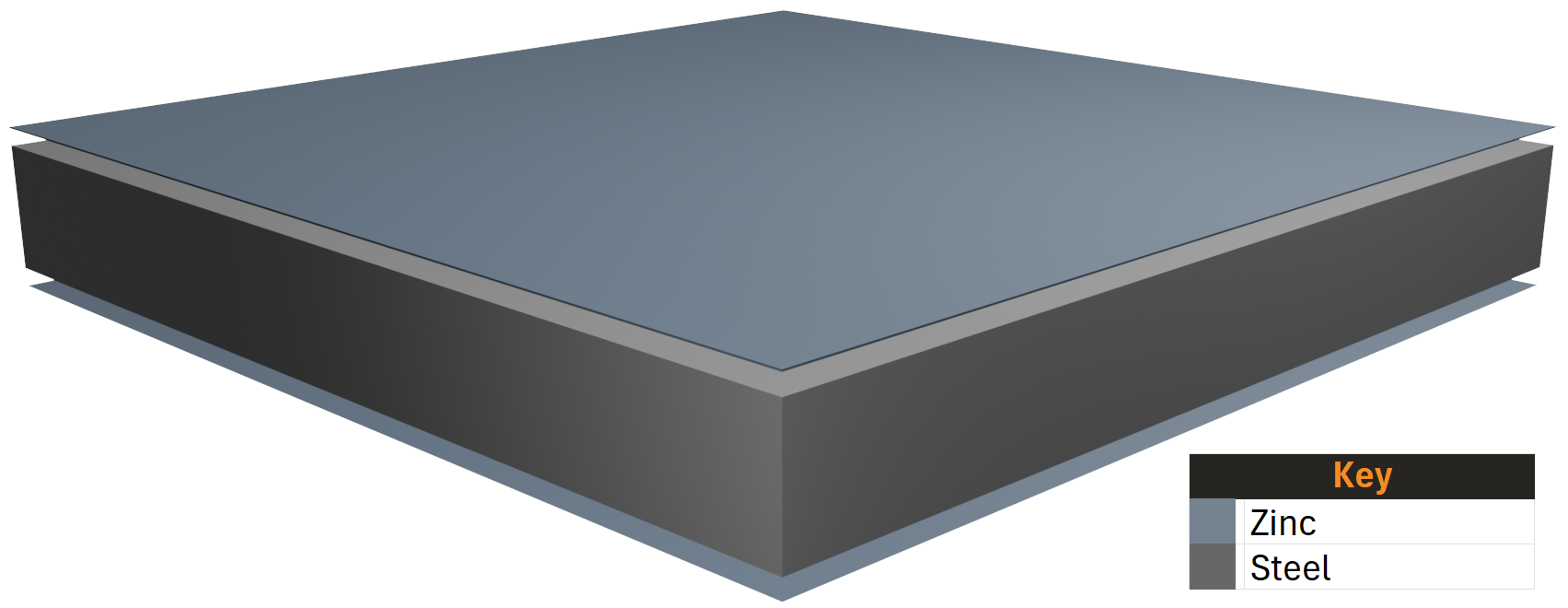

Galvanised

Galvanised sheeting is manufactured from high‑quality hot‑dipped zinc‑coated steel. No additional surface treatments are applied, making it the base substrate for several of our enhanced finishes, including Polyester Paint and PVC Plastisol‑coated roofing sheets.

Galvanised steel has been widely used for more than a century due to its inherent durability. When installed and maintained correctly, it offers a long service life. However, the material remains vulnerable to corrosion, particularly once the zinc layer becomes compromised and the underlying steel is exposed. For this reason, galvanised sheets are not recommended for use within three miles of coastal environments, where salt exposure can significantly reduce lifespan.

It is important to note that galvanised steel will naturally weather over time, resulting in a progressively duller appearance. Surface aesthetics can also vary considerably between batches, so if colour uniformity or visual consistency is required, a coated product is strongly advised.

Galvanised steel is sometimes mistaken for stainless steel, but these are fundamentally different materials with distinct performance characteristics and corrosion‑resistance mechanisms.

Freshly galvanised sheets cannot be painted immediately. The surface must first weather and stabilise, which typically requires around six months. For applications requiring an immediate or more durable coloured finish, Polyester‑coated or PVC Plastisol‑coated sheets are recommended.

Galvanised steel is not supplied as a colour finish, and its appearance will not remain uniform. As the material weathers, areas of discolouration and surface roughness will develop. Where a consistent, long‑term aesthetic is required, a factory‑applied coated finish should be selected.

Appropriate storage is essential to maintain material quality. Galvanised sheets should be stored indoors at a stable temperature to prevent condensation, water ingress, and premature weathering while stacked. Degreasing the sheets prior to installation is also recommended to remove residual rolling oils, which may otherwise react during the weathering process.

Finish Properties

| Property | Unit | Value | Test Standard | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard zinc coating | (g/m2) | 275 (Z275) | |||||||||||||||||||||

| Minimum yield stress | (N/mm2) | 220 (S220GD) | EN 10147:2000 | ||||||||||||||||||||

| Bending and profiling quality | DX51D | EN 10142:2000 | |||||||||||||||||||||

| Estimated time to first maintenance*: | |||||||||||||||||||||||

|

|||||||||||||||||||||||